Impedance and Transmission Loss

Contact

Impedance and Transmission Loss

The impedance tube

The acoustics group uses a two- microphone Bruel & Kjaer 4206 impedance tube to measure the absorption coefficient and surface impedance of material samples in agreement with ISO 10534-2.

In addition, an extension with two additional microphones is used to determine the transmission loss as well as the characteristic impedance and wave number within a material.

The system consists of a 100 mm tube for a freqeuncy range of 50 - 800 Hz (1.6 kHz with a reduced microphone spacing) and a 29 mm tube for frequencies of 500 - 6400 Hz.

Data aquisition and processing is done with B&K PULSE.

Absorption coefficient and surface impedance

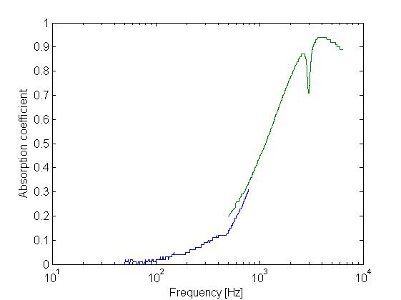

As an example, the absorption coefficient of the popular melamine foam BASF Basotect is hown in the frequency range of 50 - 6400 Hz. the blue line shows data from the large tube, the green like the corresponding data from the small tube. The sample thickness was 1" (25.4 mm).

Transmission loss, characteristic impedance and wave number

With two additonal microphones behind the sample, information about the wave components travelling in both directions is available for the cavities in front and behind the sample - as long as plane wave propagation can be assumed.

Based on the transfer matrix formualtion of the problem, the properties of the sample, especially the transmission loss, can be deduced [1].

If the sample is furthermore considered to be homogeneous, the wave number and characteristic impedance (or the complex speed of sound and the bulk density) can be determined [2].

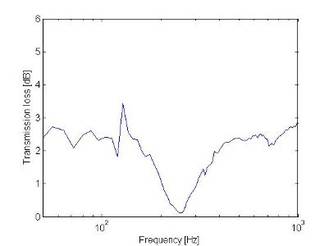

Two examples are provided in the following figures. In the first row, the transmission loss of a 100 mm diameter disc of 1" Basotect is shown: the material is almost transparent to low frequency sound.

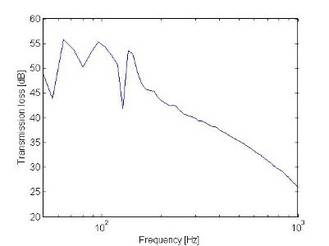

One the other hand, a 5 mm thick, lightweighted panel made from a stiff foam core covered with impregnated paper demonstrated a very high transmission loss. However, one has to keep in mind that this result is for a sample of finite size, with simply supported edges, and that an extended sample will show a much lower loss.

| | |

|  |

[1] B. H. Song and J. S. Bolton, “A transfer-matrix approach for estimating the characteristic impedance and wave numbers of limp and rigid porous materials”, J. Acoust. Soc. Am. 107, 1131-1152 (2000) [2] Allard JF., “Propagation of Sound in Porous Media: Modelling Sound Absorbing Materials.” Kluwer Academic Publishers (1993)